Why Partner with BASF?

When working with BASF as your chemical catalyst recycler, you can expect outstanding transparency, integrity and robust capabilities — all of which translates to exceptional value for your metals.

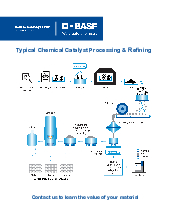

BASF also produces chemical catalysts, and we provide trading and hedging services around the globe. That means you can count on us for expertise at every stage of the product’s lifecycle.

BASF is highly specialized in this industry, as we both produce and recycle chemical catalysts. We are well-versed in every stage of a catalyst’s lifecycle and are dedicated to providing our customers with that expertise.

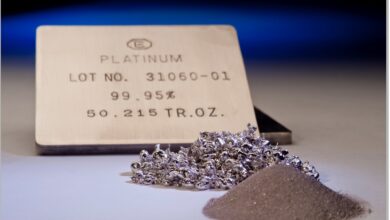

As precious metal contents vary by material, BASF has developed precise analytical and statistical methods, using ISO accredited methods, to provide our customers with a high degree of accuracy across material types.

Best Total Precious Metal Returns

With our advanced recycling equipment and precise analysis process, you can be confident knowing you’re getting the highest total return from your materials.

Global Trading and Hedging Services

Our team of experts help you to confidently navigate the PGM market with 24/7 access and a variety of settlement options.

World-Renowned Assay Lab

We are one of few refiners to employ ISO 17025/17043 accredited methods in our labs, adhering to an international standard of the competence of PGM determinations. Our team of highly trained analytical chemists provide the best analytical services representing the highest standards in the industry.

Commitment to Customer Service

We take pride in working as your business partners and delivering quick, high-value results. Our culture of integrity is reinforced by more than 150 years of experience.

End-to-End Transparency

We offer a Lot Witnessing program and encourage you to watch our processes. Each lot is evaluated for the best fit sampling and assaying processes by our team of highly trained analytical chemists.

Safe, Secure, Sustainable

We have a stable and secure presence, with financial strength and a credit rating better than most banks. We are proud to promote sustainable growth and environmental responsibility. We recognize the increasing importance of a circular economy and are in a unique position to support our partners with sustainable processes.

Find out how BASF contributes to a sustainable future here.